Newsletter nº 28

GLOMA® has already implemented the “LEAN” philosophy in its process!

LEAN?

Lean seeks to create synchronized, simplified, wasteful free and streamlined spaces and processes.

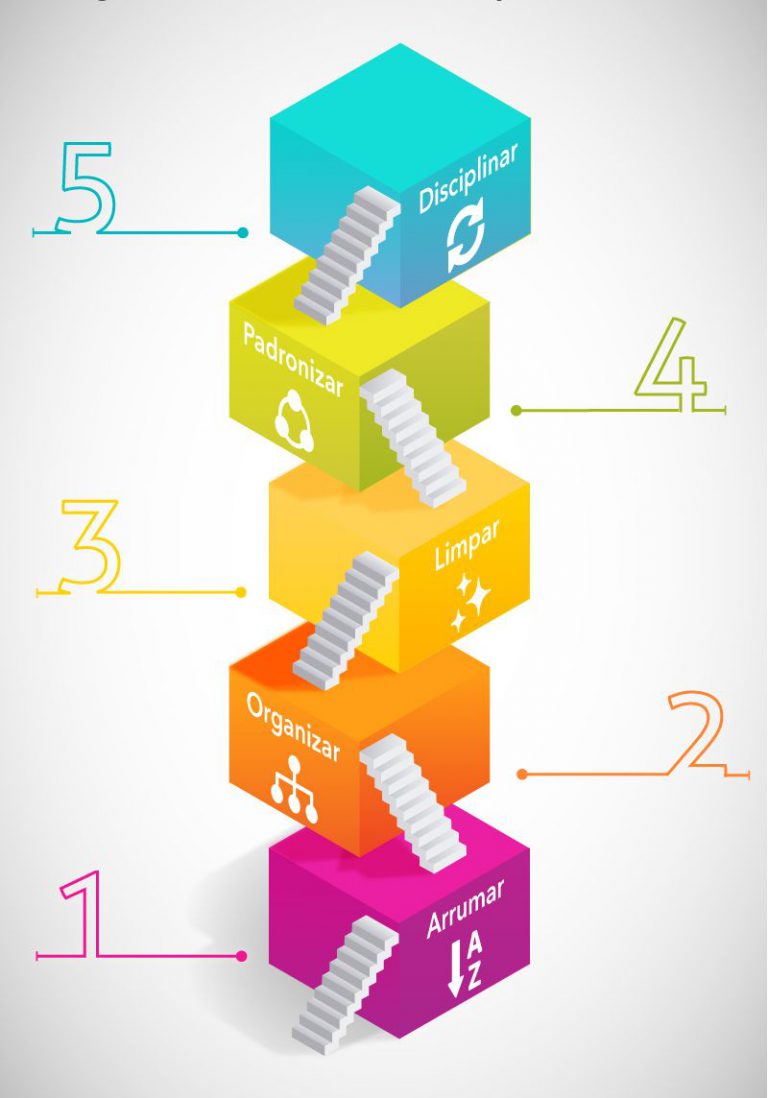

LEAN’s 5S methodology is a tool based on simple ideas that mean:

- Sort(Seiri):Analyze and separate the necessary from the unnecessary to have only what is needed, in the right quantities and only when they are necessary.

- Set in Order(Seiton): it is a process of identifying and defining the best place to store things, with each thing in its rightful place.

- Shine (Seiso): Creation of systems and methods to always keep work spaces clean.

- Standardize (Seiketsu): Create rules and define methods to maintain the good practices and results achieved.

- Disciplinar(Shitsuke): maintain the achievements made and have its principles cultivated in GLOMA®.

The Benefits?

- Increase the quality of the service provided to the client;

- Reduce waste, errors and nonconformities;

- Increase responsiveness;

- Reduce delivery times;

- Improve internal communication;

- Reduce accidents at work, increasing the safety of our employees;

But our work does not end here!

The improvement is on going, always with the aim of promoting satisfaction to our customers!